1.The selection of thyristor in series and parallel resonant circuit

When thyristors are used in series and parallel resonant circuit, the gate trigger pulse should be strong, current and voltage should be balance, and the conduction and recovery characteristics of devices should to be selected with the same performance. Especially if the devices are operating with higher di/dt of inverter circuit in series, the reverse recovery characteristics play a major role in balancing the dynamic voltage.

2.Assembly of heat sink and device

The cooling mode of assemblies include natural cooling with heat sink, forced air cooling and water cooling. In order to enable the device employ the rated performance reliably in application, it is necessary to choose a suitable water cooling heatsink and assemble it with device properly. Such to ensure the thermal resistance Rj-hs between heat sink and thyristor/diode chip meets the cooling requirement. The measurements should be considered as below:

2.1The contact area of the heat sink must match the size of device to avoid flattening or crooked damage of the device.

2.2The flatness and cleanness of heat sink contact area must be highly finished. It is recommended that the surface roughness of the heat sink is less than or equal to 1.6μm, and the flatness is less than or equal to 30μm. During assembly, the contact area of device and heat sink should keep clean and free of oil or other dirt.

2.3Make sure the contact area of device and the heat sink are basically parallel and concentric. During assembly, it is necessary to apply the pressure through the centerline of the component so that the press force is evenly distributed over the entire contact area. In manually assembling, it is recommended to use a torque wrench to apply even force to all tightening nuts in turn, and the pressure should meet the recommended data.

2.4Please pay more attention to check the contact area is clean and flat if repeat using the water cooling heat sink. Make sure there is no scale or blockage in the water box cavity, and especially no sagging on contact area surface.

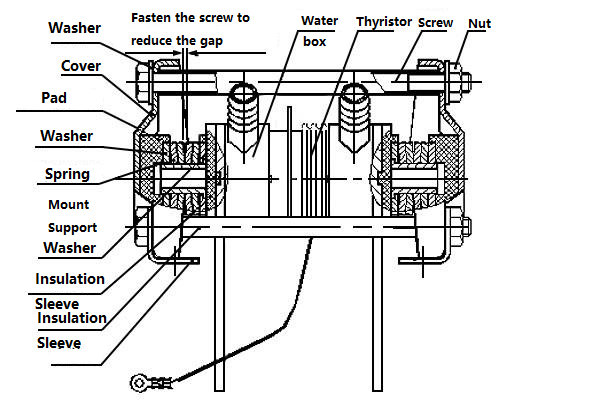

2.5 The assembly drawing of water cooling heat sink

The most important issue to ensure the reliable performance of circuit is to select the qualified device and heat sink. The high power capsule thyristor and diode manufactured by Runau Semiconductor are highly lighted in line frequency applications. The featured voltage ranges from 400V to 8500V and current ranges from 100A to 8KA. It’s excellent in strong gate trigger pulse, pretty balance of conducting and recovery characteristics. The water cooling heat sink is designed and manufactured by CAD and CNC facilities. It’s helpful to enhance the operating performance of devices.

Post time: Apr-07-2022